Products

-

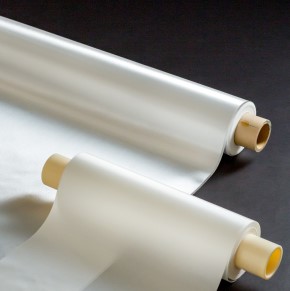

Quartz cloth SQX series

The SQX (quartz cloth) series is core materials of low-dielectric substrates and a cloth product for pre-preg of CCL (Copper Clad Laminate) board.

Details of product

Compared to conventional glass cloth, SQX has low dielectric and low dielectric loss tangent, it is suitable for base material for high-frequency substrates and FRP.

In addition, since SQX has a coefficient thermal expansion of about 1/10 that of general glass cloth, SQX can be used as a material for thin package substrates.

SQX can also be considered as a low alpha ray material.

-

Low dielectric material SLK series

The SLK series has top-class low-dielectric and low-dielectric loss tangent as thermosetting resins.

Details of product

In particular, SLK has excellent characteristics in the high frequency band such as millimeter waves, and SLK can be used for next-generation interlayer insulating films, copper-clad laminates (CCL), and flexible substrates (FCCL).

SLK has possible to design high-adhesion and low-warp coating materials by using it.

-

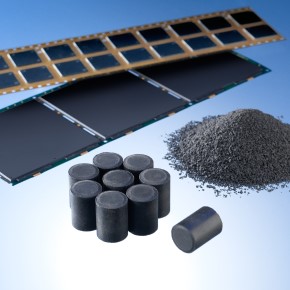

Epoxy molding material KMC series

KMC series, Shin-Etsu Chemical's semiconductor encapsulation material, is an epoxy molding compound which is using by advanced technology through development of silicone, and is a transfer molding material for encapsulation of various electronic components.

Details of product

KMC series are having excellent low stress and low warpage, as well as high heat resistance and high thermal conductivity.

Shin-Etsu supply highly reliable encapsulation materials not only for general semiconductors device but also for large in-vehicle power modules and various sensor applications.

-

Liquid epoxy encapsulation material SMC series

SMC series are liquid epoxy encapsulation materials developed for potting materials, adhesives, and underfill materials for semiconductor devices.

Details of product

The semiconductor device which is protected by this encapsulation material has excellent electrical properties and moisture resistance.

In addition, the low stress properties by using silicone which is Shin-Etsu Chemical's original technology, shows excellent properties in heat resistance.

-

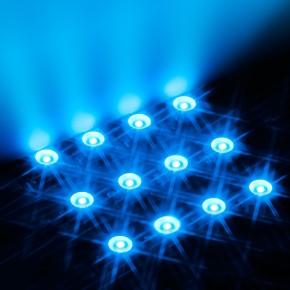

High-purity, high-transparency silicone material for LED

LPS seriesShin-Etsu Chemical's LPS series are silicone resin for various LEDs (white LEDs, ultraviolet LEDs, blue LEDs) encapsulation and packaging materials.

Details of product

High-performance LED devices can be produced by taking advantage of this material characteristics such as long-term durability, high-temperature stability, high adhesiveness, and high refractive index under high-temperature operation due to the high brightness LEDs. When encapsulating the LED semiconductor chip used for the white light source, mix it with a phosphor.

Shin-Etsu have a wide range of silicone products from soft gels to hard types which can be applied for transfer molding. Shin-Etsu can supply grades that meet customer needs.

-

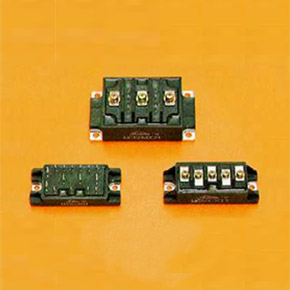

Silicone resin for high pressure resistance and high heat resistance device coating KJR series

Shin-Etsu Chemical's silicone resin for high-voltage and high-heat-resistant device coating is a polyimide silicone that stabilizes the PN junction surface, minimizes leakage current, and protects against mechanical impact and contaminants of diodes and transistors, KJR series have excellent heat resistance, electrical characteristics in a wide frequency range, and high adhesive to various substrates, and is effective in improving reliability.

Details of product

-

High thermal conductivity silicone material

Shin-Etsu has a highly adhesive and heat resistant type silicone materials that takes advantage characteristics of silicone resin. This material can be used to fix the heat dissipation fins, the die attach material etc., this material can improve the reliability and stability of heat generating equipment.

Details of product

“SAHF” which is intentionally forms a heat dissipation path, is a sheet material with low elasticity unique to silicone. “SAHF” has an unprecedented high thermal conductivity, and can meet the requirement of high heat dissipation from chip.

-

Silicone coating material / adhesive

Shin-Etsu's silicone-coating material plays a big role in achieving better performance of semiconductor device for electrically protects of semiconductor elements. It can used for surface coating material of semiconductor devices which has various properties such as high adhesiveness, heat resistance improvement, moisture resistance improvement, and internal stress relief.

Details of product

Shin-Etsu have a wide range of products from gel to rubber to meet customer requirement.

Shin-Etsu also provide UV + heat and thermosetting materials that can be used for lid seals and adhesion to urethane. This material has excellent internal stress relief and high adhesion to the target object.

This material has excellent light resistance (prevention of coloring by light), thermal stability, and adhesion to inorganic substances, which is used by advantages of silicone characteristics. It can be used not only for semiconductor applications but also as a protective material for various materials.

-

Silicone for Liquid crystal electrode protection

Shin-Etsu Chemical's liquid crystal electrode protection silicone is manufactured based on strictly process and quality control, and is variety of products which is from UV cureable type to room temperature curable type. It will be able to shorten cure time for large size of liquid crystal panel.

Details of product

-

Silicone sheet LPS series

Shin-Etsu Chemical's silicone sheet is made to process a special silicone into a sheet. This special silicone gives self-adhesiveness, high elasticity, high adhesiveness, and transcription, in addition to the high reliability (heat resistance and light resistance) which is having silicone. By mixing a phosphor with this self-adhesive silicone sheet, it can be used as a wavelength conversion film. By sticking it on the surface of the LED chip, it can easily convert the blue color emitted by the LED into light of various colors such as white etc., and make the colors look uniform.

Details of product

-

LED reflector TGR series

A reflector for LED is a component to increase brightness that reflects the light emitted by LED. By using a reflector made of silicone, it has excellent heat and weatherable resistance. It contributes to a wide range of LED’s applications with extending the shelf life of LED light. With high processing technology, it is possible to apply various package shapes.

Details of product

-

D/A material (B stage agent, silicone)

Shin-Etsu Chemical's B-stage material is a high-purity and electric non-conductance die-attach material which is developed for stencils or screen printing. It shows good plate releaseablity, shape retention, and storage stability at the B stage condition (a semi-cured status that is apparently cured without tack). After bonding the chips, it can handled in the same way as thermosetting resin which is remelted by heating at high temperature. It is showed high stress resistance after curing.

Details of product

In addition, Shin-Etsu Chemical's silicone die-attach material is a highly adhesive die-attach material that controls outgassing during curing and suppresses contamination of wire pads.

It exhibits a wide range of low modulus and low pollution with unique technologies of silicone, so it can be applied not only to LED but also to sensors and semiconductor applications.

-

Highly transparent epoxy

Shin-Etsu Chemical's highly transparent epoxy molding material is a transfer molding compounds with high transmittance, high heat resistance, and high weatherable resistance.

Details of product

It can meet any applications from customer, especially required high reliability, such as car devices etc.

-

White highly reflective material

Shin-Etsu Chemical offers a variety of white highly reflective materials from liquid to tablet shapes. Liquid materials have extremely high reflectance, and can use suitable for processes (dispensing and printing). It is also used for dam agents, and apply it to customer’s desired design.

Details of product

The transfer-molded tablet material is an epoxy-based white reflector material that features high reflectance, high injection properties, and low warpage. It has excellent heat resistance and weatherable resistance. It is contributed to extend the shelf life of LED devices.

-

Silicone impregnation agent

Shin-Etsu Chemical's silicone impregnation agents are characterized by high insulation and water repellent.

Details of product

Compared to water and organic oils, it has a significantly smaller surface tension and can easily invade even small gaps in electronic components. It is prevented the intrusion of residues which is generated during plating process, and contributes to high moisture resistance of electronic components.

-

High-purity silane gas KA series

Shin-Etsu Chemical's high-purity silane gas are used wide range of applications for electronics applications such as most advanced logic semiconductor, insulation of memory devices and epitaxial thin films of analog devices, as well as fiber applications that are raw materials for optical fiber synthetic quartz, and modification agent of fuel-saving tire rubber of automobiles.

Details of product

It is contributed to the achievement of SDGs with materials.

Shin-Etsu Chemical's high-purity silane gas are ultra-high purity materials by advanced refining technology and ultra-trace analysis technology, strict quality control backed by many years of Shin-Etsu Six Sigma activities, and thorough container clean management. By high quality and stability of impurities reduced to the utmost limit, it will be able to meet the diverse requirement and earn the trust from customers at all over the world.

-

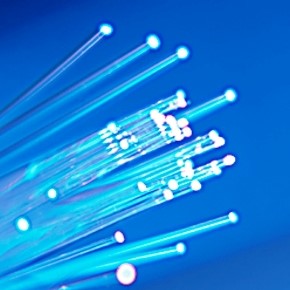

Optical fiber coating material OF series

Optical fiber coating material is protects the surface of very thin optical fiber with a cross section diameter of 125 μm and improves strength with excellent in heat resistance, cold resistance, and demonstrates stable function over a wide temperature range.

Details of product

Besides the heat curing type, there are products of UV curing type corresponding to high speed drawing.

-

Silicone molding compound SGC series

Shin-Etsu Chemical is offer silicone molding compound which can be thermosetting transfer molding system for electric and electronic parts. It is contained various fillers and additives based on silicone resin. It has excellent heat resistance, cold resistance and degradation resistance. It is shown stable electrical insulation performance because it is not changing properties by temperature and frequency. In addition, mold releasability is excellent.

Details of product

Shin-Etsu responds to molding material that requires high heat resistance.

-

Room temperature storable

Dry ice free packing

Details of product

Energy saving for storage

-

Low temperature or short time curable

Energy saving at production process

Details of product

-

No waste or simple packing

Reduce the loss during production

Details of product

Saving containers and packaging materials

-

Low risk for health and environment

Formulated without health concerned material

Details of product